Shop

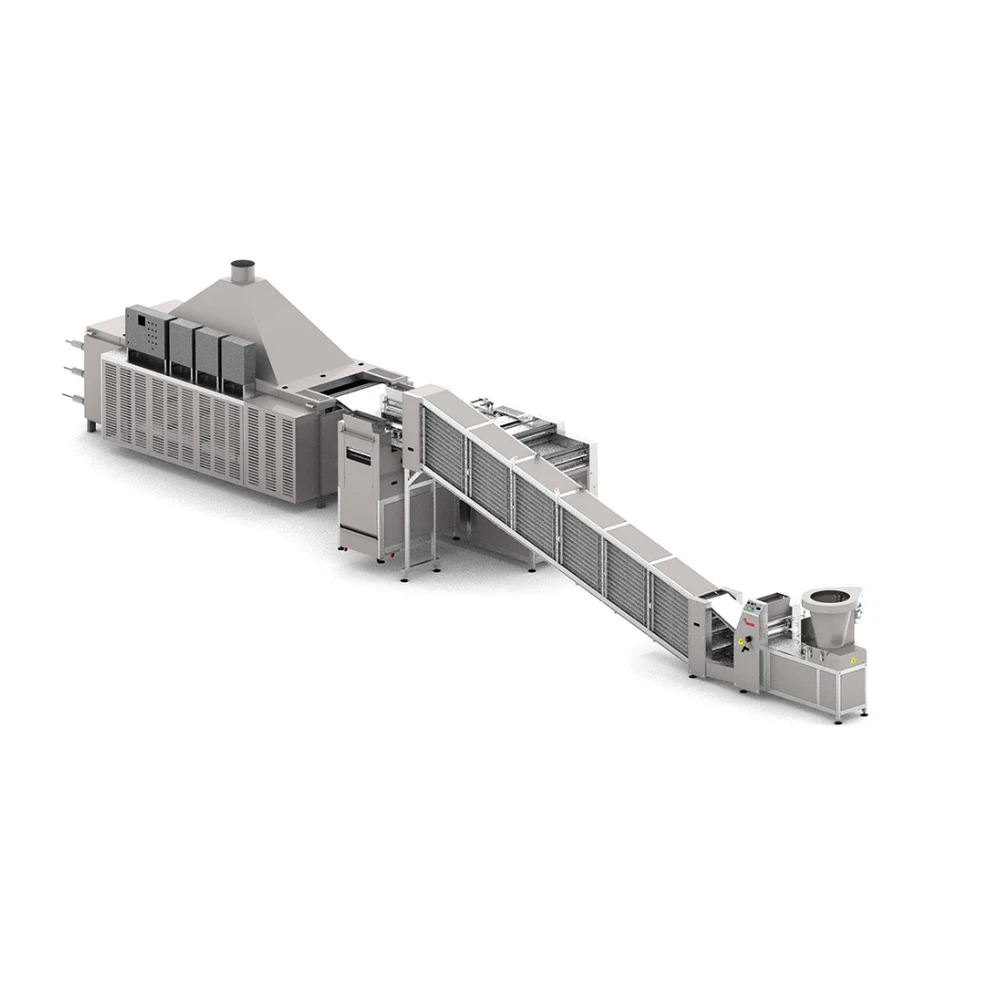

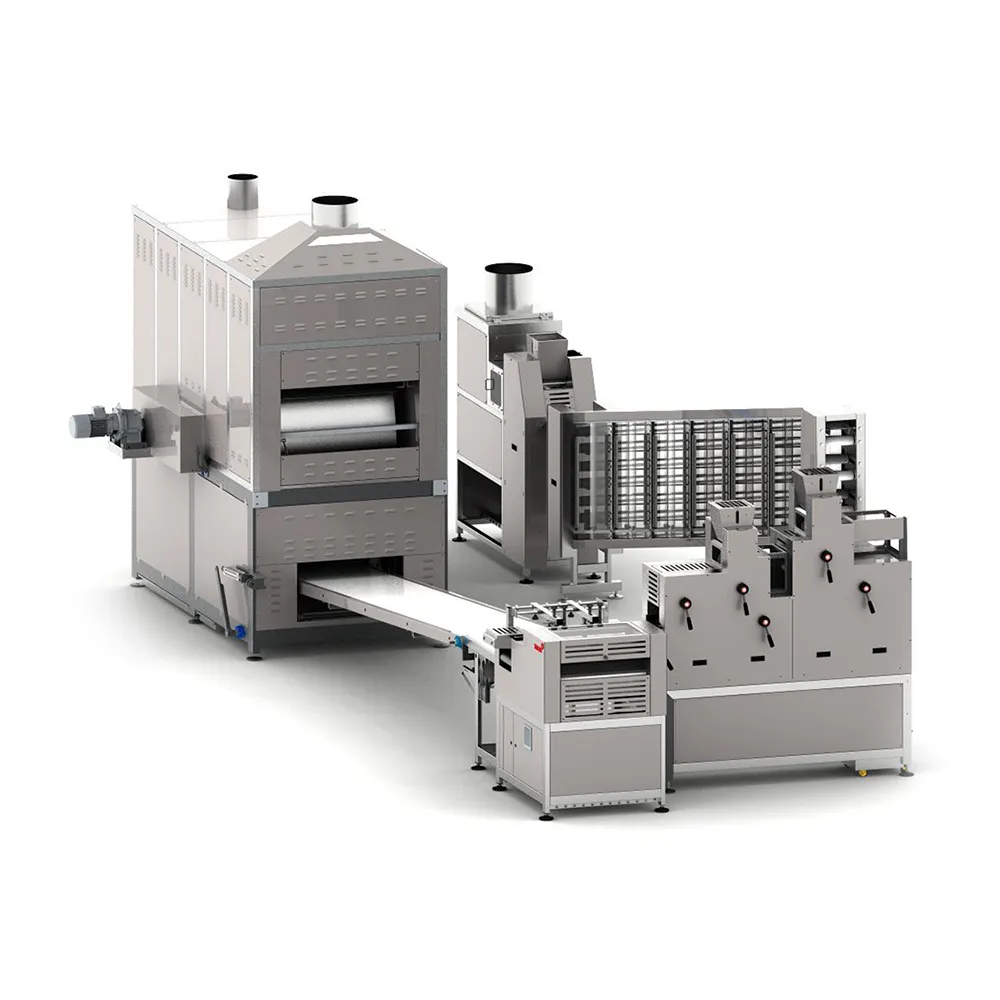

Tortilla

This flexible and efficient tortilla line is ideal for medium to large-scale production, offering high performance, consistency, and ease of operation.

Physical Dimensions • External Dimensions: - Length: 11m - Height: 2.2m - Width: 3.5m • Footprint Area: Approx. 150 square meters Capacity and Performance • Production Capacity: Up to 4,000 tortillas/hour. • Dough Weight Range: 30–120 grams. • Product Size Range: Diameter: 150–300 mm. • Energy Consumption: - Gas: 40 m³/hour. Material and Build: • Materials Used: - Stainless steel or painted steel for durability and hygiene. - Food-grade belts for handling dough safely. - Oven-grade bricks ensure optimal baking performance. • Finish: - Non-stick food-grade surface coating. • Durability Features: - Corrosion-resistant and easy-to-maintain design. Technical Specifications • Power Supply Requirements: 380-220V, 50/60 Hz, 3-phase connection. • Control System: PLC system. • Automation Level: Fully automated • Speed Control: adjustable speed for dough feeding, baking, and cooling. Operational Features • Temperature Range: 300°C. • Cooking/Baking Technology: High-efficiency gas tunnel oven with evenly distributed heat zones. • Safety Features: - Emergency stop buttons. - Overheating and pressure control mechanisms. • Noise Levels: 65–75 dB at full capacity. • Recommended Running Hours: Up to 12 hours/day. Compliance and Standards • Certifications: CE, CSA, UL certification, ISO 9001 compliance. • Hygiene Standards: Food-grade materials and design, adhering to international food safety standards. Optional Add-ons • Accessories: - Automatic stacking and counting systems. - Inline packaging systems. • Customization Options: Modular designs for tailored layouts and production requirements. Maintenance and Usability • Cleaning Features: - Smooth, food-grade surfaces for easy cleaning. - Detachable components for quick access. • Maintenance Requirements: - Routine checks are recommended every 500 hours of operation. - Easy-to-replace parts for minimal downtime. • Usability Features: - Ergonomic design for operator comfort.

Physical Dimensions • External Dimensions: - Length: 11m - Height: 2.2m - Width: 3.5m • Footprint Area: Approx. 150 square meters Capacity and Performance • Production Capacity: Up to 4,000 tortillas/hour. • Dough Weight Range: 30–120 grams. • Product Size Range: Diameter: 150–300 mm. • Energy Consumption: - Gas: 40 m³/hour. Material and Build: • Materials Used: - Stainless steel or painted steel for durability and hygiene. - Food-grade belts for handling dough safely. - Oven-grade bricks ensure optimal baking performance. • Finish: - Non-stick food-grade surface coating. • Durability Features: - Corrosion-resistant and easy-to-maintain design. Technical Specifications • Power Supply Requirements: 380-220V, 50/60 Hz, 3-phase connection. • Control System: PLC system. • Automation Level: Fully automated • Speed Control: adjustable speed for dough feeding, baking, and cooling. Operational Features • Temperature Range: 300°C. • Cooking/Baking Technology: High-efficiency gas tunnel oven with evenly distributed heat zones. • Safety Features: - Emergency stop buttons. - Overheating and pressure control mechanisms. • Noise Levels: 65–75 dB at full capacity. • Recommended Running Hours: Up to 12 hours/day. Compliance and Standards • Certifications: CE, CSA, UL certification, ISO 9001 compliance. • Hygiene Standards: Food-grade materials and design, adhering to international food safety standards. Optional Add-ons • Accessories: - Automatic stacking and counting systems. - Inline packaging systems. • Customization Options: Modular designs for tailored layouts and production requirements. Maintenance and Usability • Cleaning Features: - Smooth, food-grade surfaces for easy cleaning. - Detachable components for quick access. • Maintenance Requirements: - Routine checks are recommended every 500 hours of operation. - Easy-to-replace parts for minimal downtime. • Usability Features: - Ergonomic design for operator comfort.

Pita Chip Master

Designed to streamline the production of pita chips with precision and efficiency, making it an ideal solution for bakeries and snack manufacturers.

Variant • Width 400mm • Width 800mm • Width 1000mm Material • Stainless steel Specifications • The length of the pita chips can be controlled by the user. • Electric operated with 2 variable speed motors • Rotary blade for length adjustment based on blade speed. • Shear chopping blades for fixed chip width. • Easy to clean and maintain

Variant • Width 400mm • Width 800mm • Width 1000mm Material • Stainless steel Specifications • The length of the pita chips can be controlled by the user. • Electric operated with 2 variable speed motors • Rotary blade for length adjustment based on blade speed. • Shear chopping blades for fixed chip width. • Easy to clean and maintain

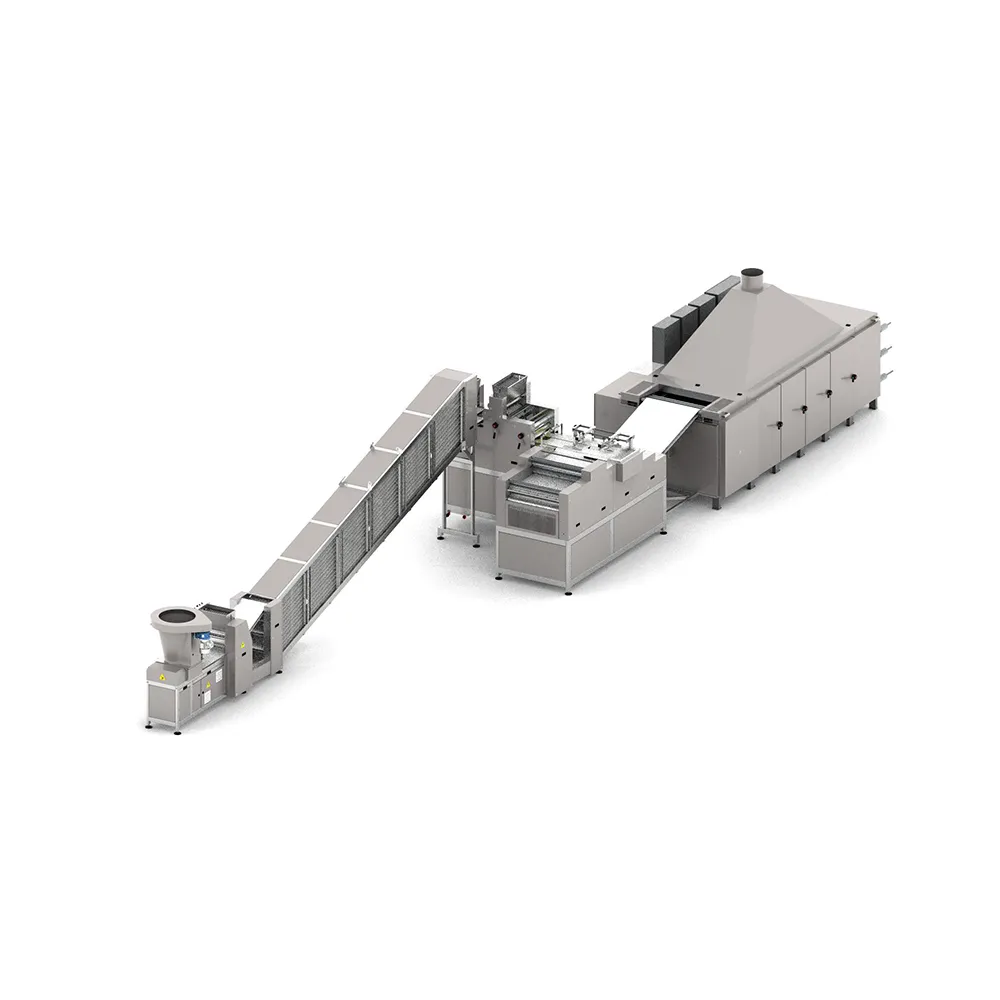

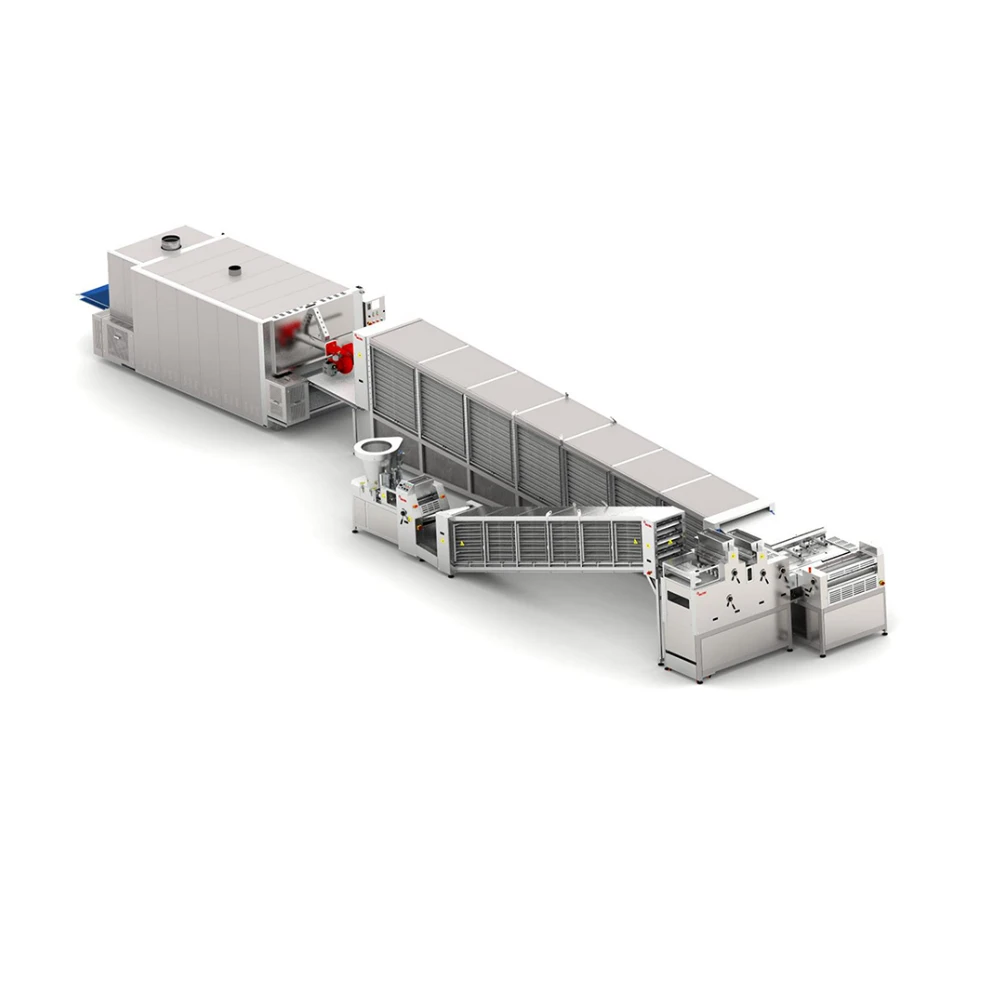

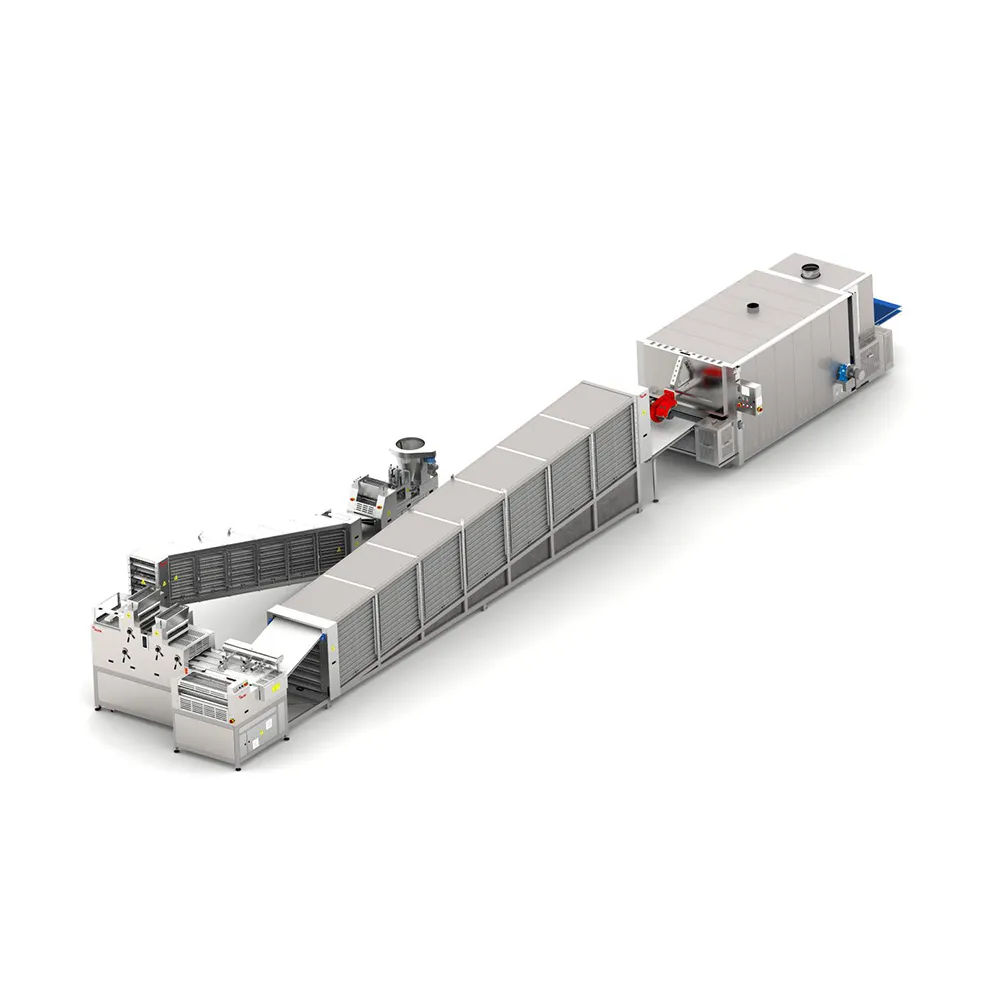

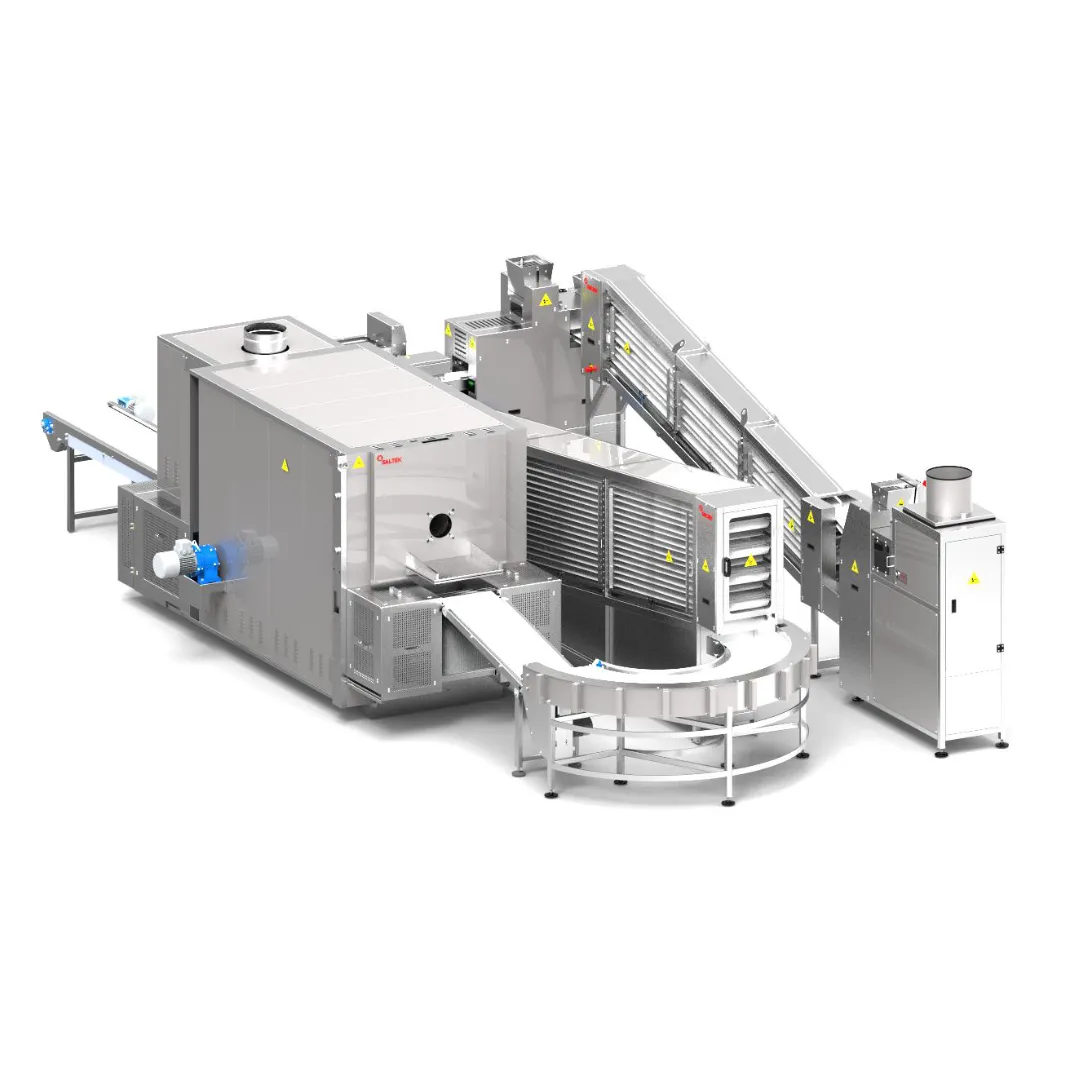

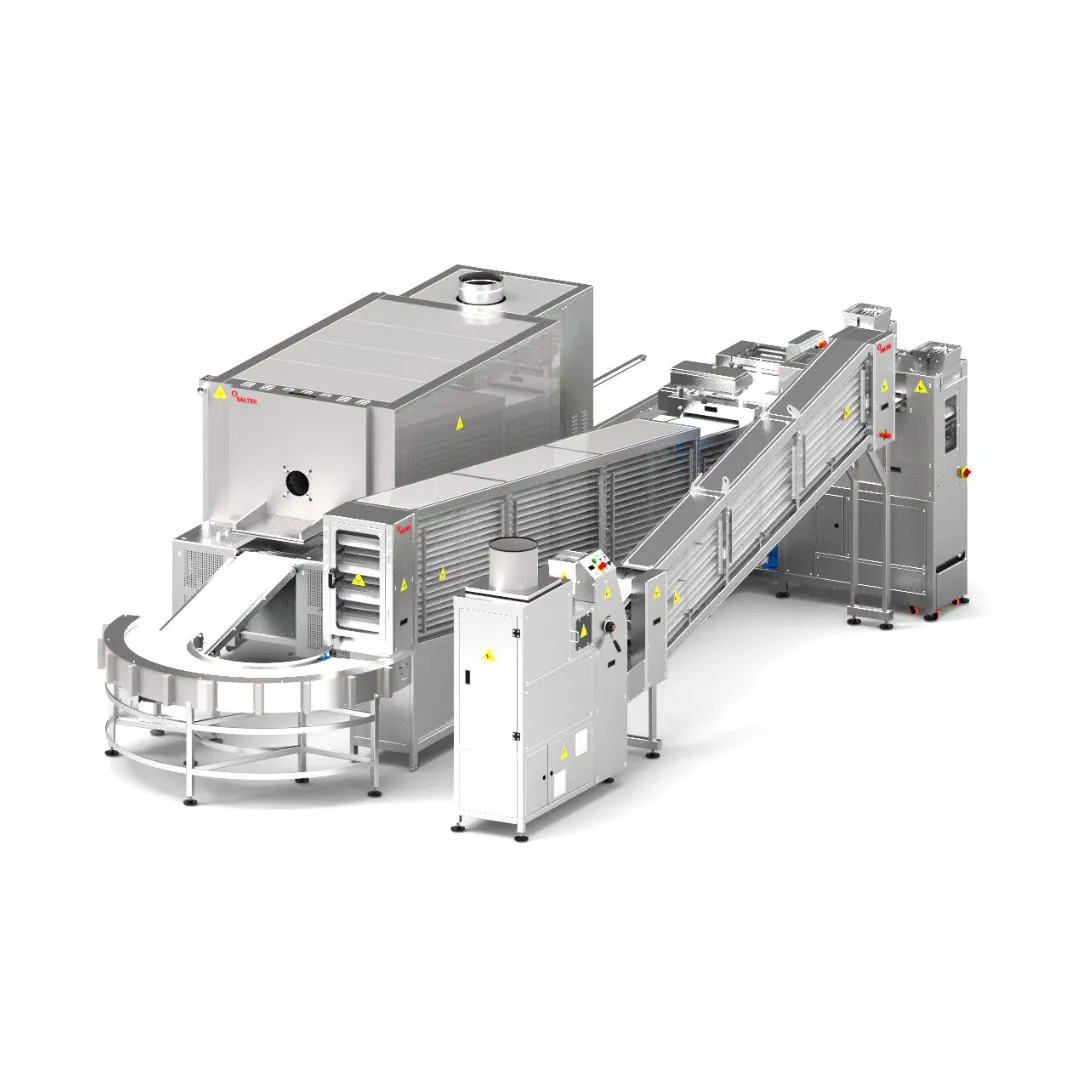

Pita Line Pro

SALTEK’s industrial line is designed for maximum efficiency, scalability, and versatility, making it suitable for large-scale bakery operations

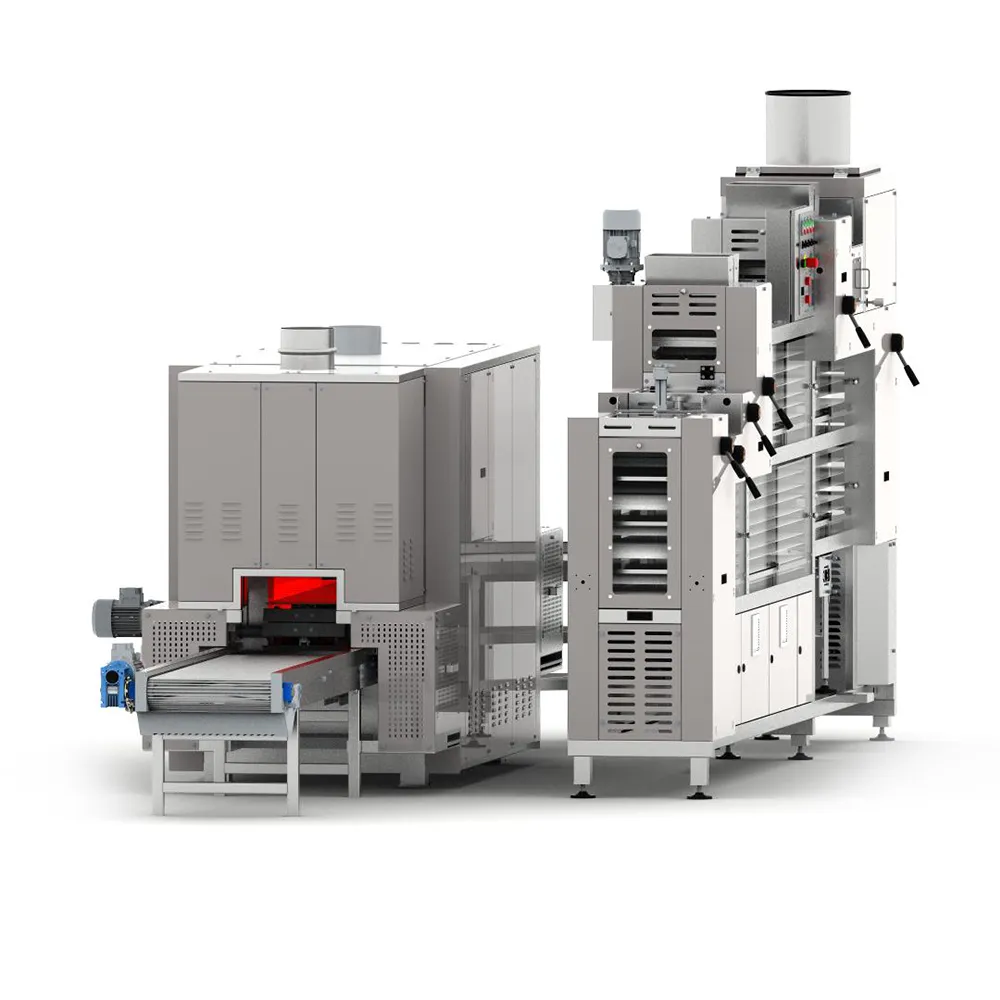

Compact & Compact Flexible

SALTEK’s Compact Line is tailored for small to medium-scale bread production, offering efficient performance, ease of use, and flexibility in layout and capacity.

MiniSmart

The SALTEK MiniSmart Line is designed to combine compactness with performance, making it ideal for small to medium-scale bakeries looking for an efficient, versatile, and easy-to-operate production solution.

Physical Dimensions: • External Dimensions: Length: 3.98 m, Width: 1.92 m • Footprint Area: Compact design requiring minimal space for installation and operation, approximately 50 m2 Capacity and Performance: • Production Capacity: Up to 750 loaves/hour. • Dough Weight Range: Handles dough balls ranging from 40-150 grams. • Product Size Range: Produces bread with a diameter of 150-270 mm. • Energy Consumption: - Electricity: 3.5 kW/hr. - Gas: 26 m³/hr (if applicable). - Diesel: 18.75 m³/hr (if applicable). Material and Build: • Materials Used: - Stainless steel for durability and hygiene. - Food-grade belts for handling dough safely. - Oven-grade bricks ensure optimal baking performance. • Finish: - Non-stick food-grade surface coating. • Durability Features: - Corrosion-resistant and easy-to-maintain design. Technical Specifications: • Power Supply Requirements: 380/220V, 50/60 Hz. 3-phase • Control System: PLC system • Automation Level: Fully automatic. • Speed Control: Adjustable speed for precise control over production. Operational Features: • Temperature Range: 430°C (optimal baking temperature). • Cooking/Baking Technology: Gas or diesel burners with adjustable heat zones for consistent baking. • Safety Features: - Emergency stop button. - Overheating protection. • Noise Levels: Low operational noise: ~65 dB at full capacity. • Recommended Running Hours: Up to 12 hours/day. Compliance and Standards: • Certifications: Complies with CE, CSA, and UL standards for safety and quality. • Hygiene Standards: Designed to meet international food safety requirements. Optional Add-ons: • Accessories: - Automatic loaders for improved workflow. • Customization Options: Modular design to accommodate specific customer needs. Maintenance and Usability: • Cleaning Features: Detachable components and easy-to-clean surfaces for efficient cleaning. • Maintenance Requirements: Low maintenance, with recommended checks at regular intervals. • Usability Features: - Ergonomic design for operator comfort.

Physical Dimensions: • External Dimensions: Length: 3.98 m, Width: 1.92 m • Footprint Area: Compact design requiring minimal space for installation and operation, approximately 50 m2 Capacity and Performance: • Production Capacity: Up to 750 loaves/hour. • Dough Weight Range: Handles dough balls ranging from 40-150 grams. • Product Size Range: Produces bread with a diameter of 150-270 mm. • Energy Consumption: - Electricity: 3.5 kW/hr. - Gas: 26 m³/hr (if applicable). - Diesel: 18.75 m³/hr (if applicable). Material and Build: • Materials Used: - Stainless steel for durability and hygiene. - Food-grade belts for handling dough safely. - Oven-grade bricks ensure optimal baking performance. • Finish: - Non-stick food-grade surface coating. • Durability Features: - Corrosion-resistant and easy-to-maintain design. Technical Specifications: • Power Supply Requirements: 380/220V, 50/60 Hz. 3-phase • Control System: PLC system • Automation Level: Fully automatic. • Speed Control: Adjustable speed for precise control over production. Operational Features: • Temperature Range: 430°C (optimal baking temperature). • Cooking/Baking Technology: Gas or diesel burners with adjustable heat zones for consistent baking. • Safety Features: - Emergency stop button. - Overheating protection. • Noise Levels: Low operational noise: ~65 dB at full capacity. • Recommended Running Hours: Up to 12 hours/day. Compliance and Standards: • Certifications: Complies with CE, CSA, and UL standards for safety and quality. • Hygiene Standards: Designed to meet international food safety requirements. Optional Add-ons: • Accessories: - Automatic loaders for improved workflow. • Customization Options: Modular design to accommodate specific customer needs. Maintenance and Usability: • Cleaning Features: Detachable components and easy-to-clean surfaces for efficient cleaning. • Maintenance Requirements: Low maintenance, with recommended checks at regular intervals. • Usability Features: - Ergonomic design for operator comfort.

Stacking Machine

SALTEK’s high-performance stacking machines offer a rational and efficient solution for pita bread stacking. Designed with simplicity, versatility, and safety in mind, this state-of-the-art equipment can stack any number of loaves per pack depending on bread diameter. Built to meet the highest safety standards, the machine ensures smooth operation while optimizing performance for bakeries of all sizes.

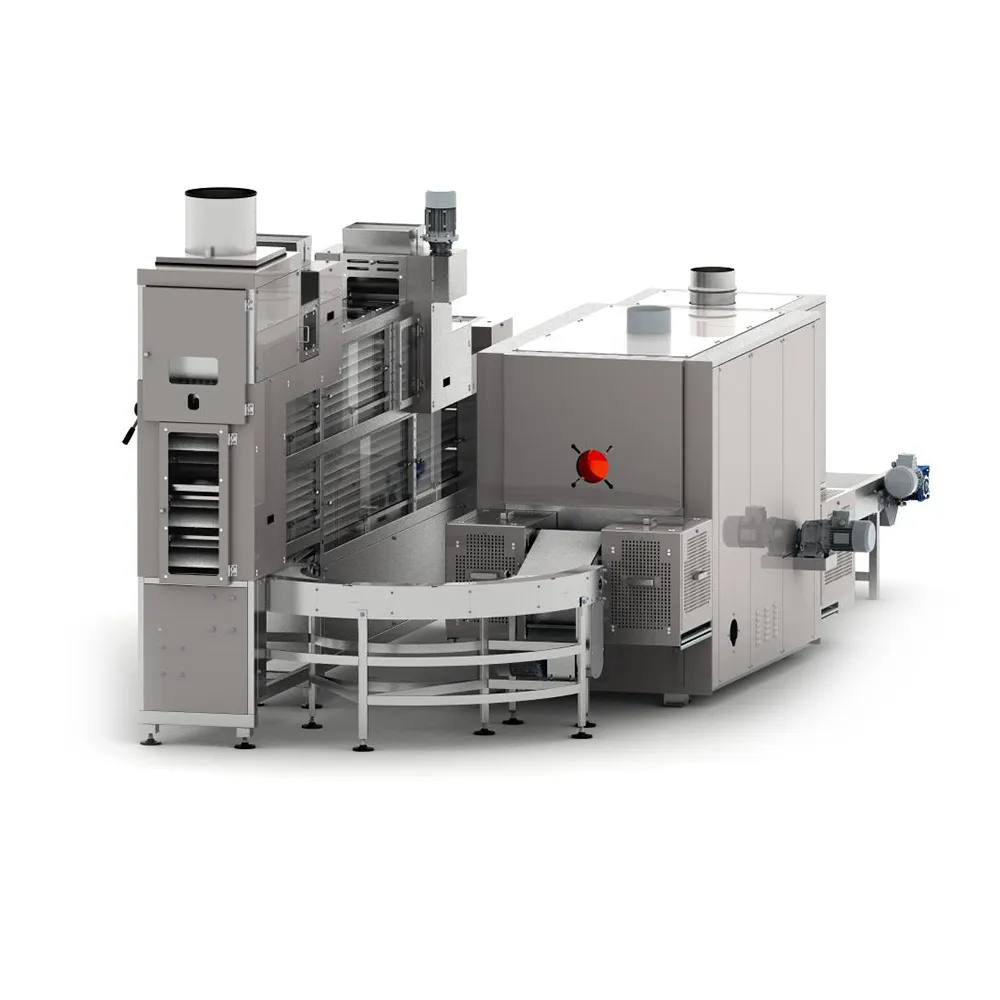

Tannour Master

The Tannour Line by SALTEK offers a robust, efficient, and customizable solution for producing traditional Tannour bread with modern precision and consistency.

Physical Dimensions • External Dimensions: - Length: Approximately 12 m • Footprint Area: Approximately 50 square meters, depending on the configuration. Capacity and Performance • Production Capacity: Up to 1500 loaves/hour. • Dough Weight Range: 50-90 grams. • Product Size Range: Diameter of bread: 18-26 cm. • Energy Consumption: - Electricity: 5–8 kW/hour (depending on machine configuration). - Gas: 26 m³/hour. Material and Build: • Materials Used: - Stainless steel or painted steel for durability and hygiene. - Food-grade belts for handling dough safely. - Oven-grade bricks ensure optimal baking performance. • Finish: - Non-stick food-grade surface coating. • Durability Features: - Corrosion-resistant and easy-to-maintain design. Technical Specifications • Power Supply Requirements: 380-220V, 50/60 Hz. 3-phase • Control System: PLC system. • Automation Level: full automation. • Speed Control: Adjustable conveyor speeds for consistent baking. Operational Features • Temperature Range: Up to 280°C. • Cooking/Baking Technology: High-efficiency gas-powered oven with a rotating platform or conveyor belt. • Safety Features: - Emergency stop buttons. - Overheating protection. - Flame failure detection systems. • Noise Levels: Below 70 dB during operation. • Recommended Running Hours: Up to 12 hours/day. Compliance and Standards • Certifications: CE, CSA, and UL-certified; complies with international safety and quality standards. • Hygiene Standards: Food-grade materials and designs that meet global food safety regulations. Optional Add-ons • Accessories: - Automatic stacking systems. • Customization Options: - Modular designs for tailored capacity. - Integration with existing production lines. Maintenance and Usability • Cleaning Features: - Easy-to-clean surfaces. - Removable conveyor belts for thorough cleaning. • Maintenance Requirements: - Low-maintenance design with readily available spare parts. - Routine checks are recommended every 1,000 operating hours. • Usability Features: - Ergonomic controls for operator comfort. - Training support for machine operation.

Physical Dimensions • External Dimensions: - Length: Approximately 12 m • Footprint Area: Approximately 50 square meters, depending on the configuration. Capacity and Performance • Production Capacity: Up to 1500 loaves/hour. • Dough Weight Range: 50-90 grams. • Product Size Range: Diameter of bread: 18-26 cm. • Energy Consumption: - Electricity: 5–8 kW/hour (depending on machine configuration). - Gas: 26 m³/hour. Material and Build: • Materials Used: - Stainless steel or painted steel for durability and hygiene. - Food-grade belts for handling dough safely. - Oven-grade bricks ensure optimal baking performance. • Finish: - Non-stick food-grade surface coating. • Durability Features: - Corrosion-resistant and easy-to-maintain design. Technical Specifications • Power Supply Requirements: 380-220V, 50/60 Hz. 3-phase • Control System: PLC system. • Automation Level: full automation. • Speed Control: Adjustable conveyor speeds for consistent baking. Operational Features • Temperature Range: Up to 280°C. • Cooking/Baking Technology: High-efficiency gas-powered oven with a rotating platform or conveyor belt. • Safety Features: - Emergency stop buttons. - Overheating protection. - Flame failure detection systems. • Noise Levels: Below 70 dB during operation. • Recommended Running Hours: Up to 12 hours/day. Compliance and Standards • Certifications: CE, CSA, and UL-certified; complies with international safety and quality standards. • Hygiene Standards: Food-grade materials and designs that meet global food safety regulations. Optional Add-ons • Accessories: - Automatic stacking systems. • Customization Options: - Modular designs for tailored capacity. - Integration with existing production lines. Maintenance and Usability • Cleaning Features: - Easy-to-clean surfaces. - Removable conveyor belts for thorough cleaning. • Maintenance Requirements: - Low-maintenance design with readily available spare parts. - Routine checks are recommended every 1,000 operating hours. • Usability Features: - Ergonomic controls for operator comfort. - Training support for machine operation.

Gas Oven for Pastry Production – Luxurious Series 100

Gas Pastry Oven - Luxurious Series - 140cm (W) x 181cm(H) x 145 cm (D)

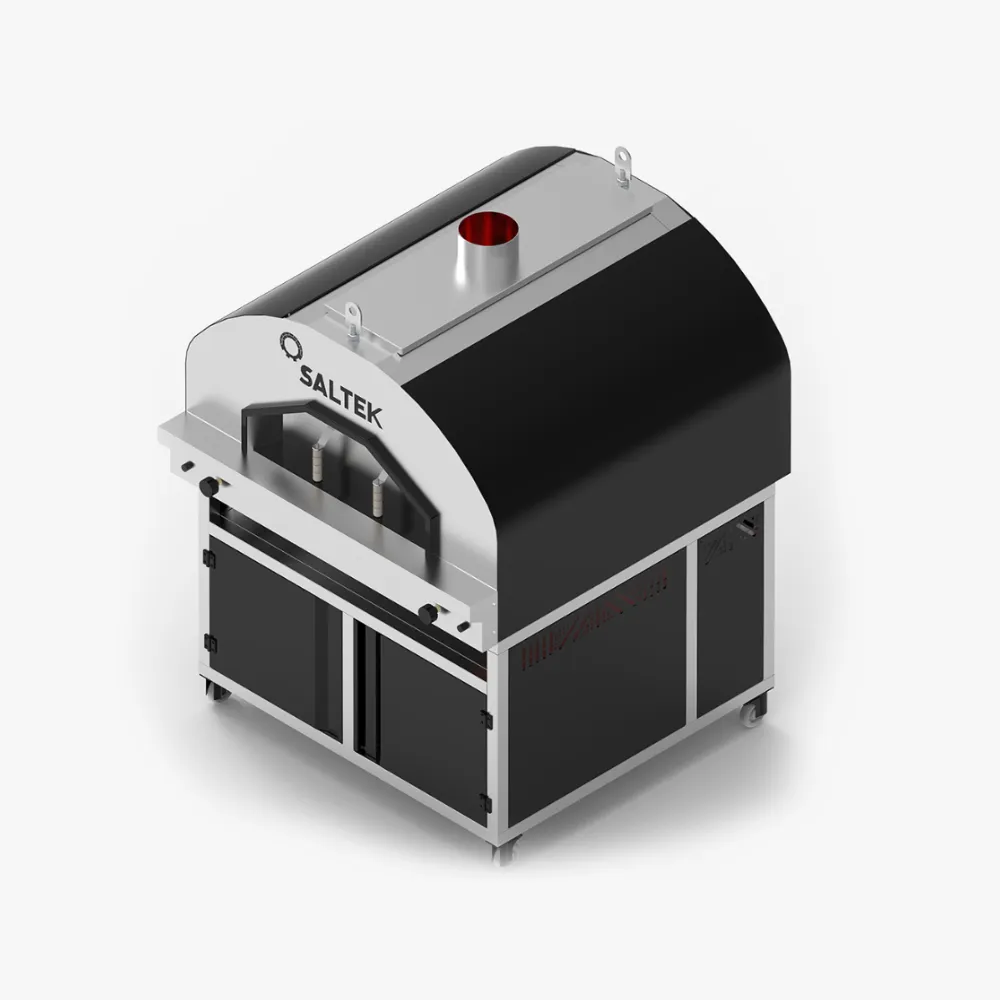

Manakish Oven

Especially designed for homes, bakeries, and restaurants, our multipurpose gas oven is ideal for baking manakish, pizza, lahmajoun, and pastries. Its innovative design ensures versatility, efficiency, and durability for diverse needs

SBE – Divider

The manakish divider automatically cuts mixed dough into equal-weight balls, with adjustable weights controlled by a built-in inverter and sensitive sensors for precise and consistent operation.

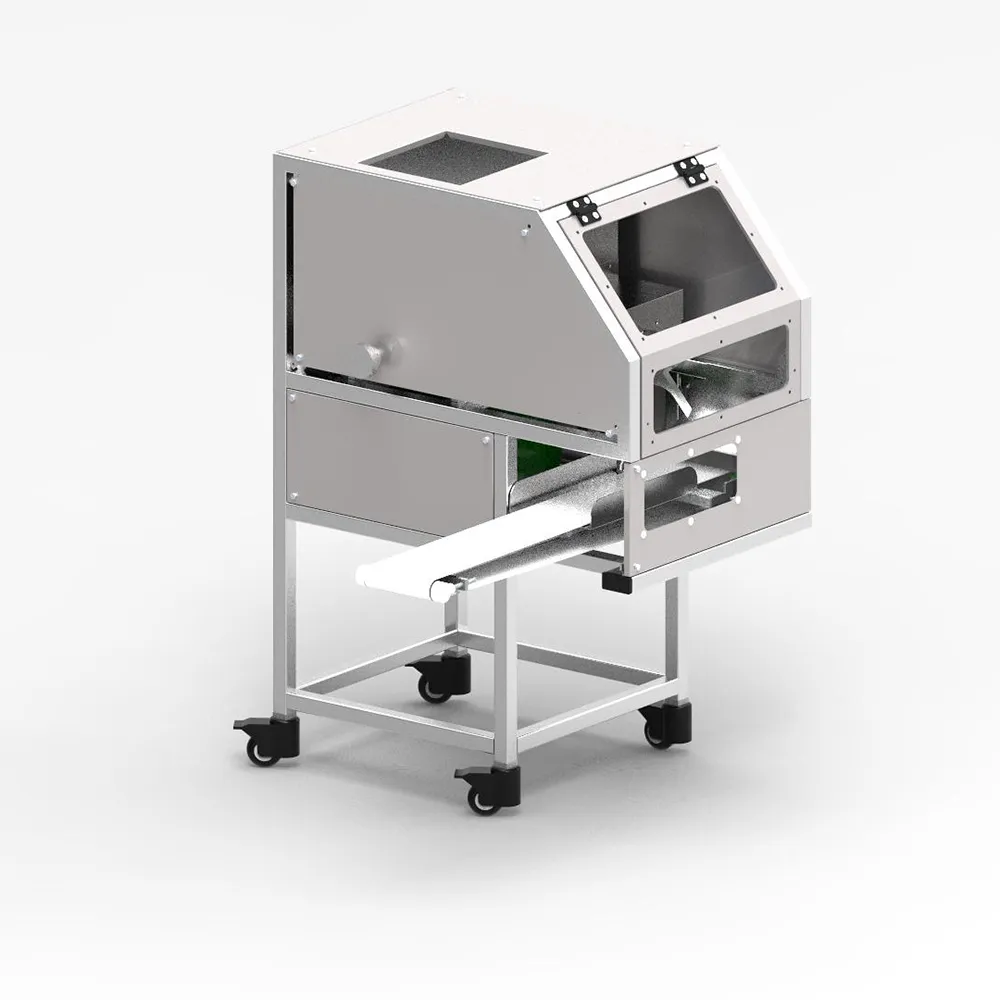

SBE – Sheeter

The manakish sheeter is ideal for kitchens, bakeries, and cafes. It efficiently flattens dough for manakish, pizza, lahmajoun, pita, and tortillas using two-cylinder sets for two-step sheeting.